OLED Distinctions

OLEDs vs. PLEDs

- Commonality: Both are organic light-emitting devices.

- Differences:

- OLEDs:

- Made from smaller organic molecules.

- Typically manufactured using vacuum evaporation techniques.

- PLEDs:

- Utilize polymers for their structure.

- Still primarily in the research phase.

- Potential for producing large, cheap, flexible displays.

- OLEDs:

AMOLED vs. PMOLED

- PMOLEDs:

- Consume more energy.

- Best suited for small screens.

- Simple and inexpensive to manufacture.

- AMOLEDs:

- Incorporate an additional layer of transistors.

- Offer faster refresh rates and lower power consumption.

- More challenging and costly to produce.

Bottom Emission vs. Top Emission vs. Transparent OLEDs

- Bottom Emission: Cathode is opaque; anode and substrate are transparent.

- Top Emission: Anode is opaque; cathode is transparent.

- Transparent OLEDs: Both the anode and cathode are transparent.

Generations of OLED Technology

- 1st Generation – Fluorescent OLEDs:

- Utilize only singlet exciton pairs.

- Maximum efficiency: 25%.

- 2nd Generation – Phosphorescent OLEDs:

- Exploit both singlet and triplet exciton pairs.

- Significantly higher efficiency compared to the first generation.

Physics of OLEDs

Traditional LED Operation

- Inject charges to fill holes and emit light.

Basic OLED Structure

- Most basic design includes three layers:

- Anode

- Cathode

- Active Layer

- Introduced around 1965.

- Process:

- Charge injection.

- Charge transport.

- Exciton formation.

- Radiative recombination.

Key Concepts

- Charge Speed: Charges must move quickly enough to form excitons before they recombine non-radiatively.

- Forward Bias: Light is emitted when the device is powered correctly.

- Reverse Bias: Occurs when the device is connected incorrectly, preventing light emission.

- Equilibrium: The device is not powered, and no light is emitted.

Electron Blocking Layer (EBL)

- Prevents excess electron migration, ensuring efficient recombination in the active layer.

Qualities of OLEDs

Luminous Efficiency

Where:

- : Driving voltage.

- : Current.

- Luminous flux.

Electroluminescence Quantum Efficiency

- Represents internal efficiency, ignoring photon transport losses.

Where:

- : Photoluminescence efficiency. Improved by suppressing non-radiative channels.

- : Ratio of singlet excitons to total excitons (max: 25%).

- : Exciton formation factor. Improved by balancing charge injection and transport.

Optimizing OLED Performance

Improving : Suppress Non-Radiative Decay Channels

- Prevent Aggregation Quenching:

- Avoid close packing of chromophores.

- Dilute active materials with a matrix substance.

- Design non-stacking chemical structures (e.g., polythiophenes, oligothiophenes).

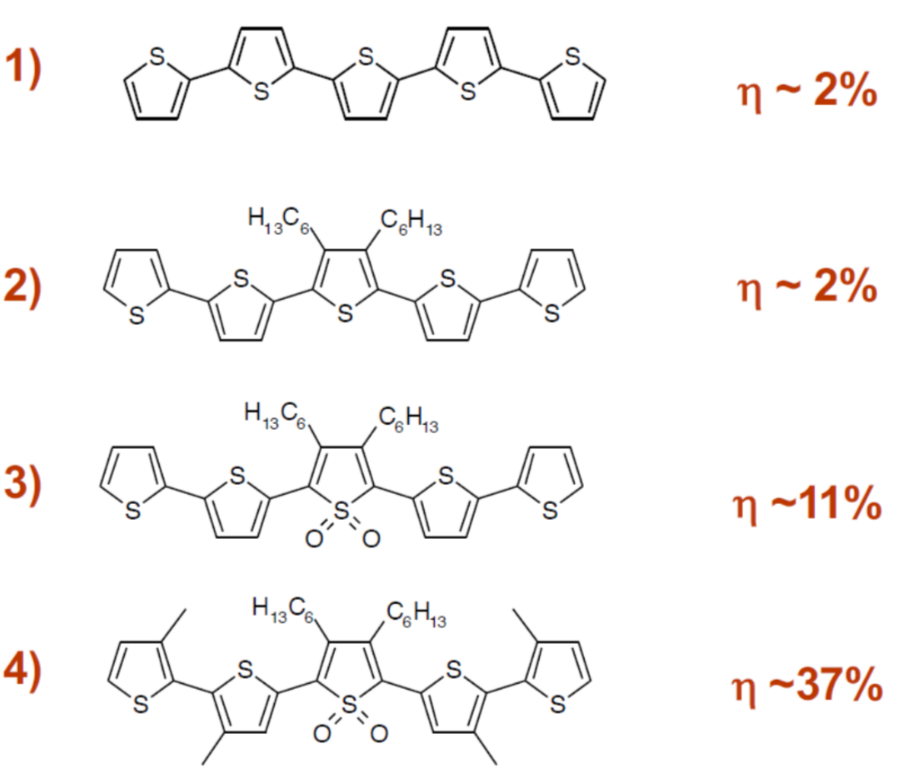

Oligothiophene efficiency increases

- Lower crystallinity improves efficiency.

- Optimize Optical Design:

- Minimize waveguiding, reabsorption, and refraction losses.

- Ensure charges recombine only in desired regions.

Increasing : Boost Radiative Excitons

- Max Efficiency: 25%.

Methods:

-

Triplet-Triplet Annihilation (TTA):

- Converts two triplets into a singlet.

- Theoretical efficiency: 62.5%.

- Practical efficiency: ~40%.

-

Thermally Activated Delayed Fluorescence (TADF):

- Reverse intersystem crossing (triplets to singlets).

- Requires complex, heavy molecules.

- Potential 100% efficiency.

-

Hybrid Local Charge Transfer (HLCT):

- Donor-acceptor molecules with similar singlet and triplet energies.

- Theoretical efficiency: 100%.

-

Harvesting Phosphorescence:

- Theoretical photoluminescence quantum yield (PLQY): 100%.

- Techniques: Foerster transfer, Dexter transfer, and E-H direct capture.

Challenges:

- Materials with low TTA.

- Blue emitters are challenging.

- Efficiency drop at high currents.

- Dexter transfer is slow due to its short range.

Improving : Enhance Charge Balance

-

Balancing Charge Injection:

- Cathode: Add alkaline materials to reduce work function.

- Anode: Modify ITO work function using:

- Self-assembled monolayers.

- Spin-coated layers.

- Layer-by-layer deposition of dedoped layers.

- Oxygen plasma treatment (standard method).

-

Balancing Charge Transport:

- Reduce excess majority carriers.

- Add separate electron and hole transporting layers.

- Form heterojunctions for efficient recombination.